Turkish armed forces get first homegrown main battle tanks

President Recep Tayyip Erdoğan on Tuesday oversaw the delivery of the first domestically developed Altay main battle tanks to the armed forces, as he reiterated Türkiye’s goal to achieve full self-sufficiency in the defense industry.

“With Altay, we have ushered in a new era in tank technology,” Erdoğan told the ceremony in Ankara.

“We are taking firm steps toward the goal of a fully independent Türkiye in the defense industry.”

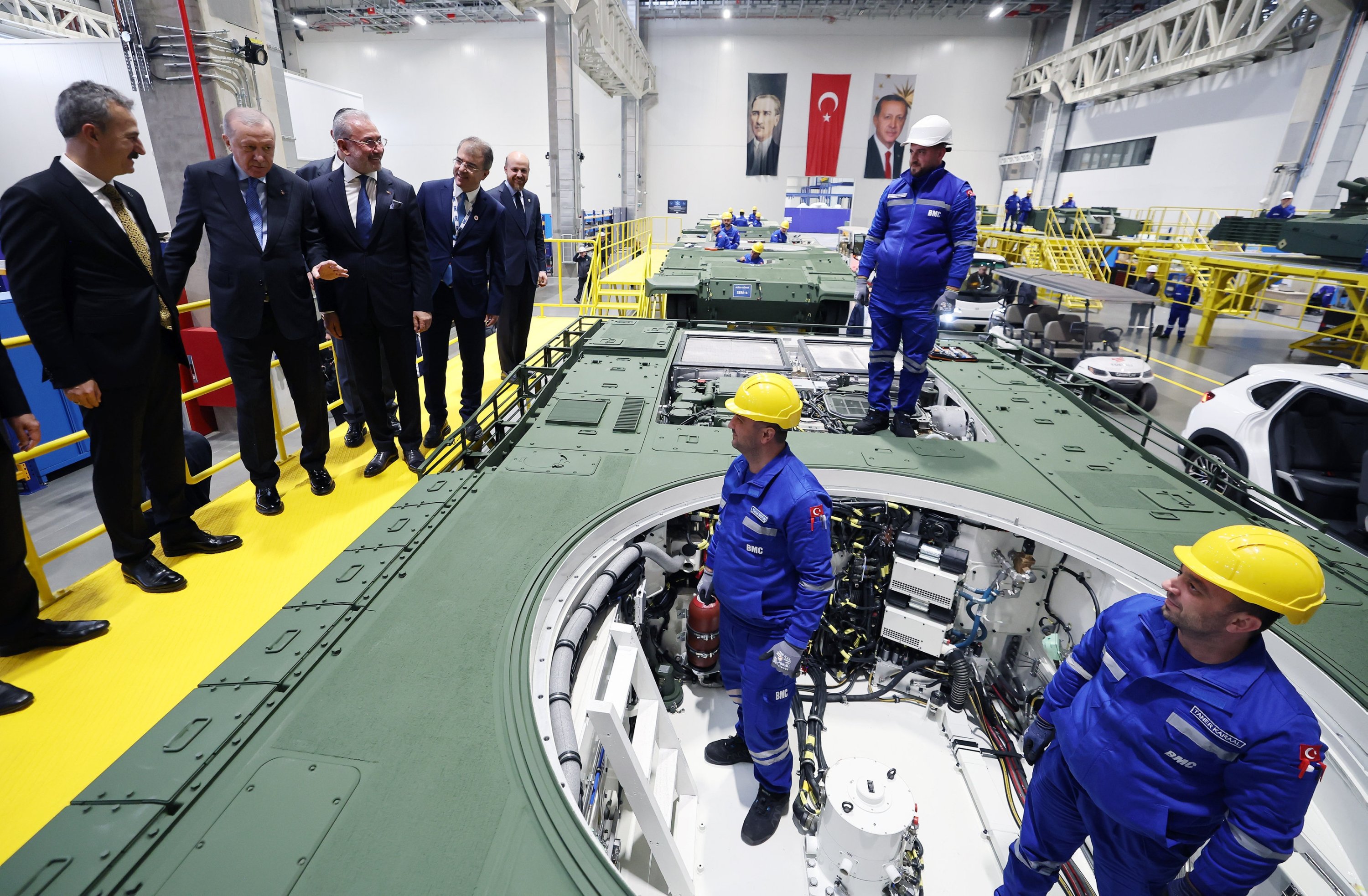

Erdoğan also officially opened the high-tech facility where the tank and its indigenous Batu power unit will be manufactured.

Eight Altay tanks will be produced a month, Erdoğan said. The BMC site will manufacture 96 platforms per year, said Defense Industries Presidency (SSB) head Haluk Görgün.

Three tanks were expected to enter the Turkish army’s inventory on Tuesday. Under the project, a total of 250 units – 85 in the T1 configuration and 165 in the T2 configuration – will be delivered to the armed forces.

The factory will also build 10 Altuğ 8×8 next-generation armored combat vehicles per month, according to Erdoğan.

The Altay project had faced obstacles and delays since its inception, mainly due to export license restrictions, but Erdoğan pushed it forward. Two prototypes were delivered for tests to the Turkish Armed Forces (TSK) in 2023.

Despite boasting NATO’s second-largest army, Türkiye often faced arms embargoes by its allies in the past. That pushed it to significantly boost domestic capabilities and curb foreign dependence over the last two decades.

Today, it produces a wide range of vehicles and arms types domestically, including its own drones, missiles and naval vessels. It’s also developing its own fifth-generation fighter jet.

“Through the steps we’ve taken over the past 23 years, especially in the defense industry, diplomacy and security, we have transformed Türkiye into a country that cannot be ignored,” said Erdoğan.

“With our state-of-the-art air, land and sea vehicles, we continue to write a new chapter in history,” he noted.

“We are no longer a nation that follows; we are now a nation that is followed.”

The external dependency in the defense industry has dropped below 20%, compared to over 80% more than two decades ago, Erdoğan said.

“We are now able to meet almost all the needs of our security forces with domestically developed defense vehicles and equipment,” he added.

Erdoğan said Türkiye is now the 11th-largest defense exporter globally.

“In 2024, we secured 65% of the global drone export market, meaning that 65 out of every 100 drones sold worldwide were supplied by us,” he noted.

“We have exported products to 180 countries, and we expect this number to grow even further in 2025.”

The Altay project is overseen by the Presidency of Defense Industries (SSB) and run by BMC, one of Türkiye’s largest manufacturers of commercial and military vehicles, as the main contractor. As many as 600 companies are said to be working on the platform.

The new generation tank’s engine is being developed by BMC’s engine and power systems division, BMC Power. The power unit continues to undergo trials, including 10,000 kilometers (6,215 miles) of road tests.

The mass production process has begun with an imported power group.

As with other defense products, Erdoğan said the “goal with the Altay tank is to avoid dependency on critical materials.”

“We have reached this stage despite the embargoes, and God willing, we will successfully carry the process forward,” said the president.

“The obstacles placed in our path may slow us down, may delay us a little, but they will never prevent us from reaching our destination.”

Altay has been upgraded to meet the conditions of modern combat environments. Many of its subsystems have been localized and will be equipped with updated technologies and innovations to enhance its combat capabilities.

Its fire control system includes modern technologies such as a laser range finder (LRF) and an advanced image stabilization system, which enable precise target detection and engagement at long distances.

Source: Daily Sabah

The BMC factory spans 840,000 square meters (9.41 million square feet), including a 63,000-square-meter indoor mass production line. It includes research and development (R&D) centers, testing grounds, armored laboratories and training tracks.

The complex will employ more than 1,500 personnel, said Erdoğan.

“From robotic welding systems to advanced sensor technologies, from simulation infrastructure to data analytics, this facility will become a comprehensive technology hub integrated into our defense ecosystem,” he noted.

Altay’s key features:

| Max speed (road) | 65 kph (40.39 mph) |

| Cross-country speed | 45 kph |

| Engine power | 1,500 horsepower (BG) |

| Engine type | 12-cylinder electronically controlled diesel |

| Transmission | 6 forward, 3 reverse – automatic |

| Suspension system | Electronic-controlled ISU with hydropneumatic leveling |

| Crew capacity | 4 (commander, gunner, loader, driver) |

| Climbing ability | Up to 60% gradient |

| Side slope capability | Up to 30% |