Glimpse into mass production of Türkiye’s homegrown main battle tank

The long-awaited mass production of Türkiye’s domestically developed main battle tank Altay is underway at a brand-new, high-tech facility in Ankara, marking a major milestone for the country’s defense industry.

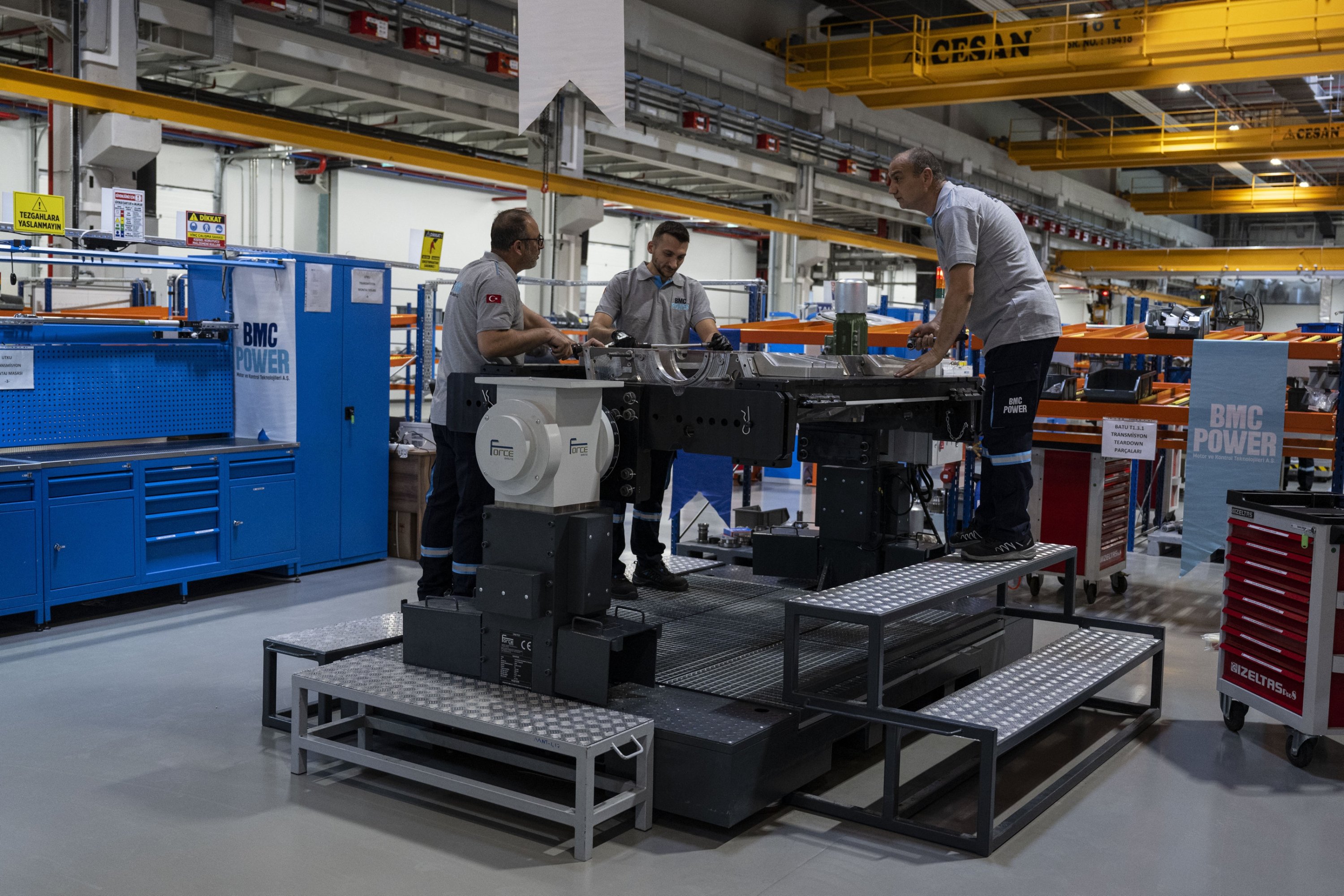

For the first time, cameras were allowed inside the BMC plant at the Aerospace and Aviation Specialized Organized Industrial Zone (HAB), where steel takes shape on the assembly line to become Türkiye’s most advanced battle tank.

The facility, built in record time and equipped with cutting-edge production technologies, will serve as the hub for both the Altay and its indigenous Batu power unit.

BMC, one of Türkiye’s largest manufacturers of commercial and military vehicles, is the main contractor in the project overseen by the Presidency of Defense Industries (SSB). As many as 600 companies are said to be working on the platform.

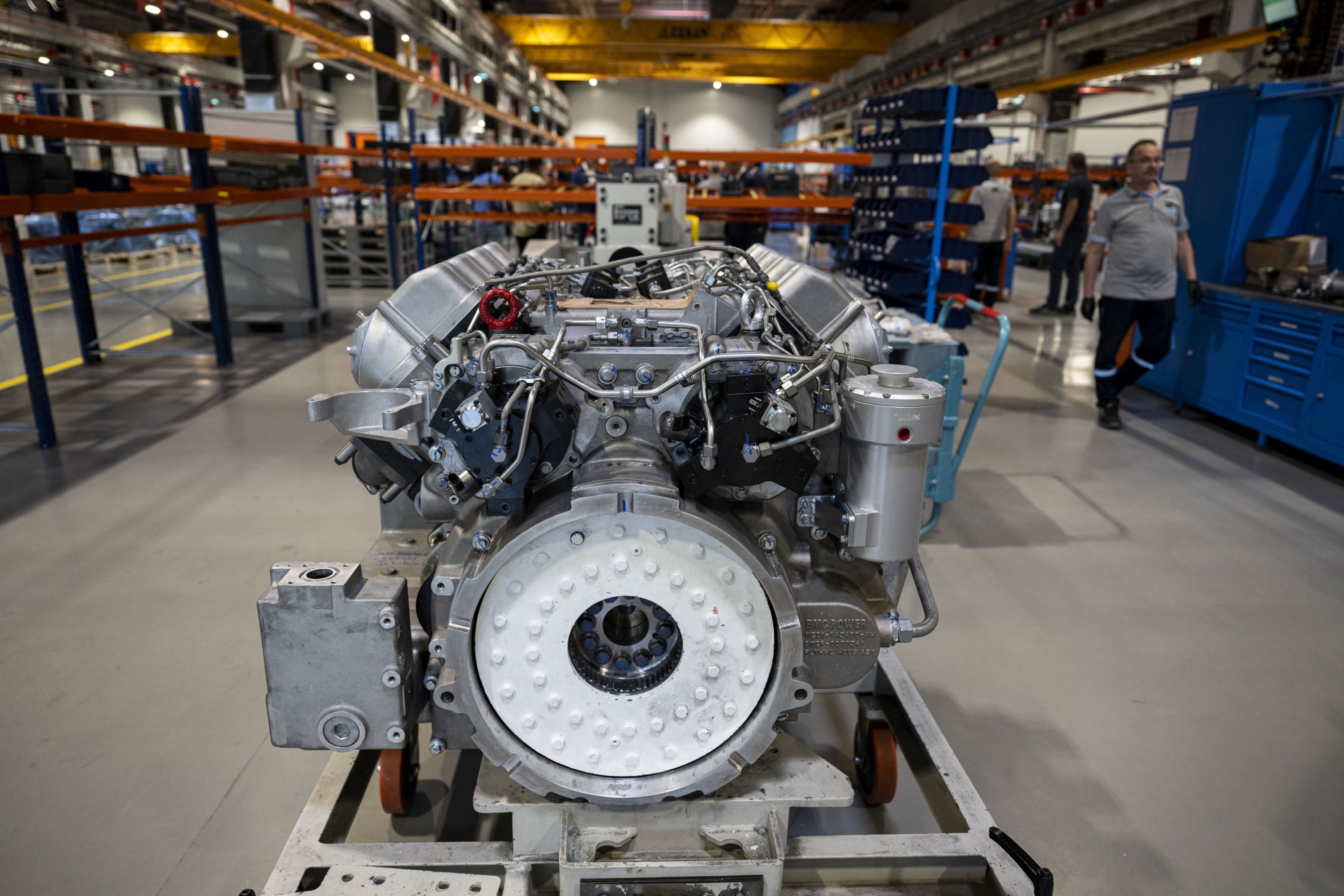

The new generation tank’s engine is being developed by BMC’s engine and power systems division, BMC Power.

Altay has been upgraded to meet the conditions of modern combat environments, according to officials. Many of its subsystems have been localized and will be equipped with updated technologies and innovations to enhance its combat capabilities.

Its fire control system includes modern technologies such as a laser range finder (LRF) and an advanced image stabilization system, which enable precise target detection and engagement at long distances.

BMC’s site in Ankara is equipped with industrial robots and next-generation production technologies to build the tank.

Walking through the plant’s production halls, BMC Chair Fuat Tosyalı described the moment as historic.

“We are proud to have realized a century-long dream for Türkiye,” he told Anadolu Agency (AA), adding that the first Altay deliveries will follow very soon.

According to the timeline, three tanks are expected to enter the Turkish army’s inventory this year. Eleven are scheduled for 2026, 41 for 2027 and 30 for 2028.

Tosyalı said domestic military engines have been developed at BMC Power since last year, with power outputs ranging from 400 to 1,500 horsepower (hp).

The unit that will power Altay, which Tosyalı described as one of the most advanced technologies in its class, continues to undergo rigorous trials, including 10,000 kilometers (6,215 miles) of road tests.

“Our power group must complete certain processes before it can be used in our tanks. It needs to run 10,000 kilometers, and it also has to pass certain performance tests. So far, there have been no setbacks in the power group’s program,” he said.

“Every component, including air defense systems, is being tested together with the tank. After all, we’re talking about a device that incorporates the most advanced technologies in the world.”

Two Altay prototypes were delivered for tests to the Turkish Armed Forces (TSK) in 2023. Tosyalı said they successfully met performance benchmarks.

The project has faced obstacles and delays since its inception, but Tosyalı credited unwavering political backing, especially from President Recep Tayyip Erdoğan and the SSB, for pushing it forward.

The new site will not only produce Altay but also BMC’s Altuğ 8×8 next-generation armored combat vehicle.

Tosyalı hopes the factory will soon be officially opened with a ceremony to be attended by Erdoğan. “We expect it to meet the needs of the Turkish Armed Forces and allied countries in the defense industry,” he said.

Below are some of Altay’s key features:

| Max speed (road) | 65 kph (40.39 mph) |

| Cross-country speed | 45 kph |

| Engine power | 1,500 horsepower (BG) |

| Engine type | 12-cylinder electronically controlled diesel |

| Transmission | 6 forward, 3 reverse – automatic |

| Suspension system | Electronic-controlled ISU with hydropneumatic leveling |

| Crew capacity | 4 (commander, gunner, loader, driver) |

| Climbing ability | Up to 60% gradient |

| Side slope capability | Up to 30% |

| Operating Temperature | -32°C (89.6°F) t |

Source: Daily Sabah