Report: Britain starts manufacturing on new fighter jet protoype

The UK has begun manufacturing and assembling the main structure of its first crewed combat air demonstrator in four decades, according to BAE Systems.

This initiative, in collaboration with Rolls-Royce, MBDA UK, and the UK Ministry of Defence (MOD), is a significant advancement in developing a piloted supersonic aircraft designed to test new technologies, including stealth features.

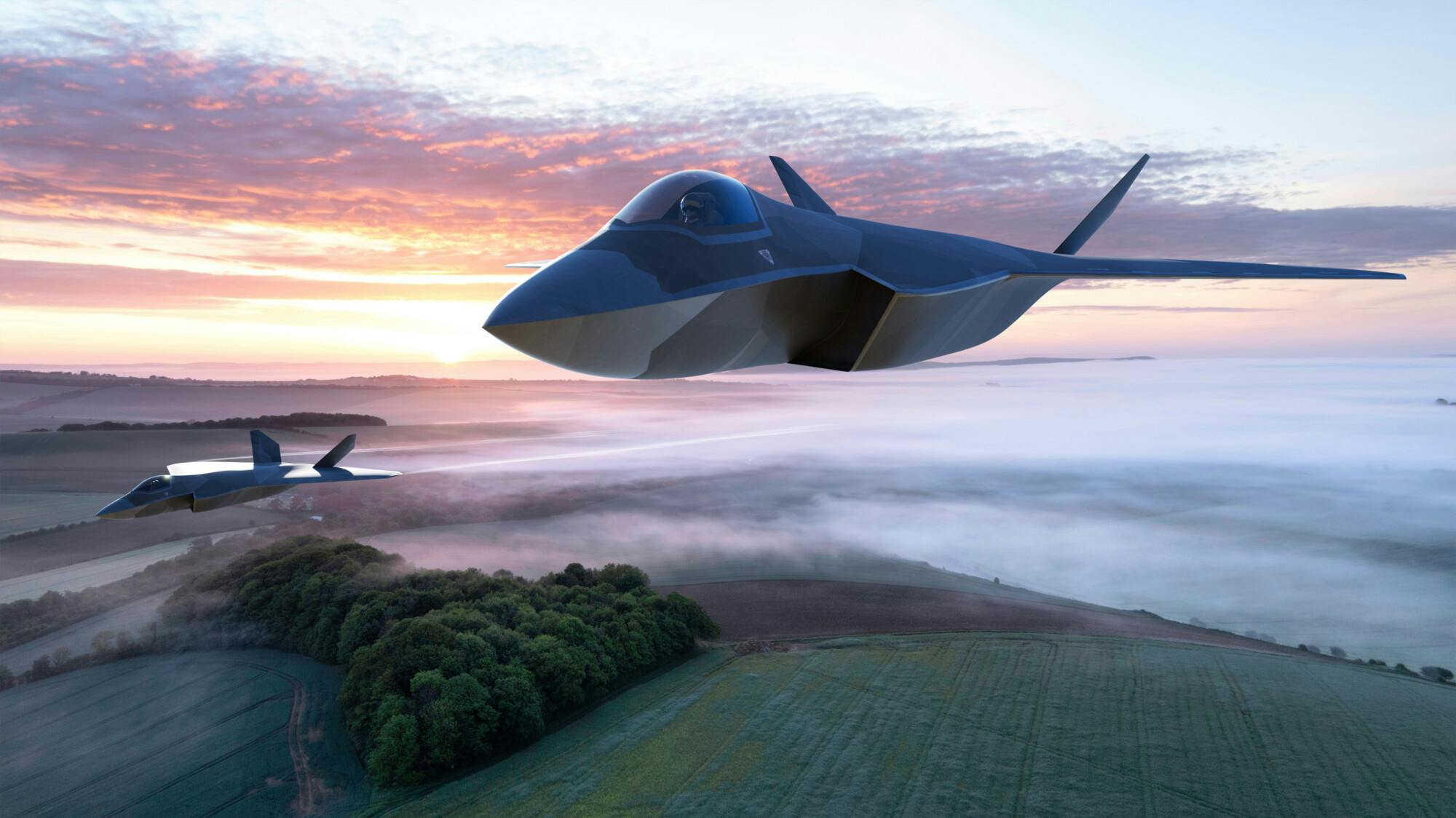

This project is a pivotal part of the Tempest programme, announced by the UK Government in July 2022, and aims to have the aircraft ready for flight within the next three years.

The Tempest initiative is expected to produce a new combat aircraft by 2035. The ongoing work, which already includes more than half of the aircraft’s weight in build, leverages the expertise of the UK’s defence industry and innovative digital techniques, such as advanced manufacturing technologies, virtual simulators, and digital rigs.

Paul Wilde, Head of Tempest at BAE Systems, spoke of the initiative’s importance for maintaining the UK’s leadership in combat aircraft design and production.

“The flying technology demonstrator is a vital initiative for developing national skills and advanced technology, ensuring the UK remains a world leader in the design, production, test and certification of combat aircraft. Partnering with around 100 UK suppliers, including our Team Tempest partners, we’re combining engineering expertise with innovative methods to enhance and refresh crucial industrial skills which is so important as we get ready to deliver the Tempest programme. The demonstrator is a ground-breaking initiative which will showcase the best of British engineering, supporting apprentices and graduates who learn from our best engineers, keeping the UK at the forefront of defence and aerospace.”

The demonstrator will offer valuable data and lessons to support the development of the new combat aircraft. BAE Systems is utilising additive manufacturing processes, including 3D printing and Hot Isostatic Press (HIP) technology, to produce significant structural parts of the aircraft efficiently and cost-effectively.

In Warton, Lancashire, test pilots from BAE Systems, Rolls-Royce, and the Royal Air Force (RAF) have conducted over 215 hours of simulation flights. This extensive simulator testing provides critical insights to support the aircraft’s design and future flight trials, allowing pilots to become familiar with the aircraft years before its maiden flight.

Additionally, digital simulators and rigs are being used to test cockpit conditions without the need for physical environmental rigs.

MBDA is collaborating with BAE Systems to trial digital weapon integration processes for the demonstrator. This early-stage collaboration aims to prove that these digital techniques can reduce the time and cost associated with weapons integration. Rolls-Royce is preparing to deliver two EJ200 engines, donated by the MOD, for installation into the demonstrator following successful integration testing last year.

Air Commodore Martin Lowe, Future Combat Air Systems Programme Director for UK Ministry of Defence, said:

“The demonstrator is helping us understand more about the advanced technology that is required to deliver a sixth-generation fighter jet. The progress we have made together – MOD and industry – in such a short space of time has been remarkable. A large part of this is down to a new generation of engineering specialists who are using innovative manufacturing solutions to deliver this demonstrator aircraft.”

The flying technology demonstrator represents a significant milestone in the Tempest programme, which will eventually be delivered through the Global Combat Air Programme (GCAP) involving the UK, Italy, and Japan.

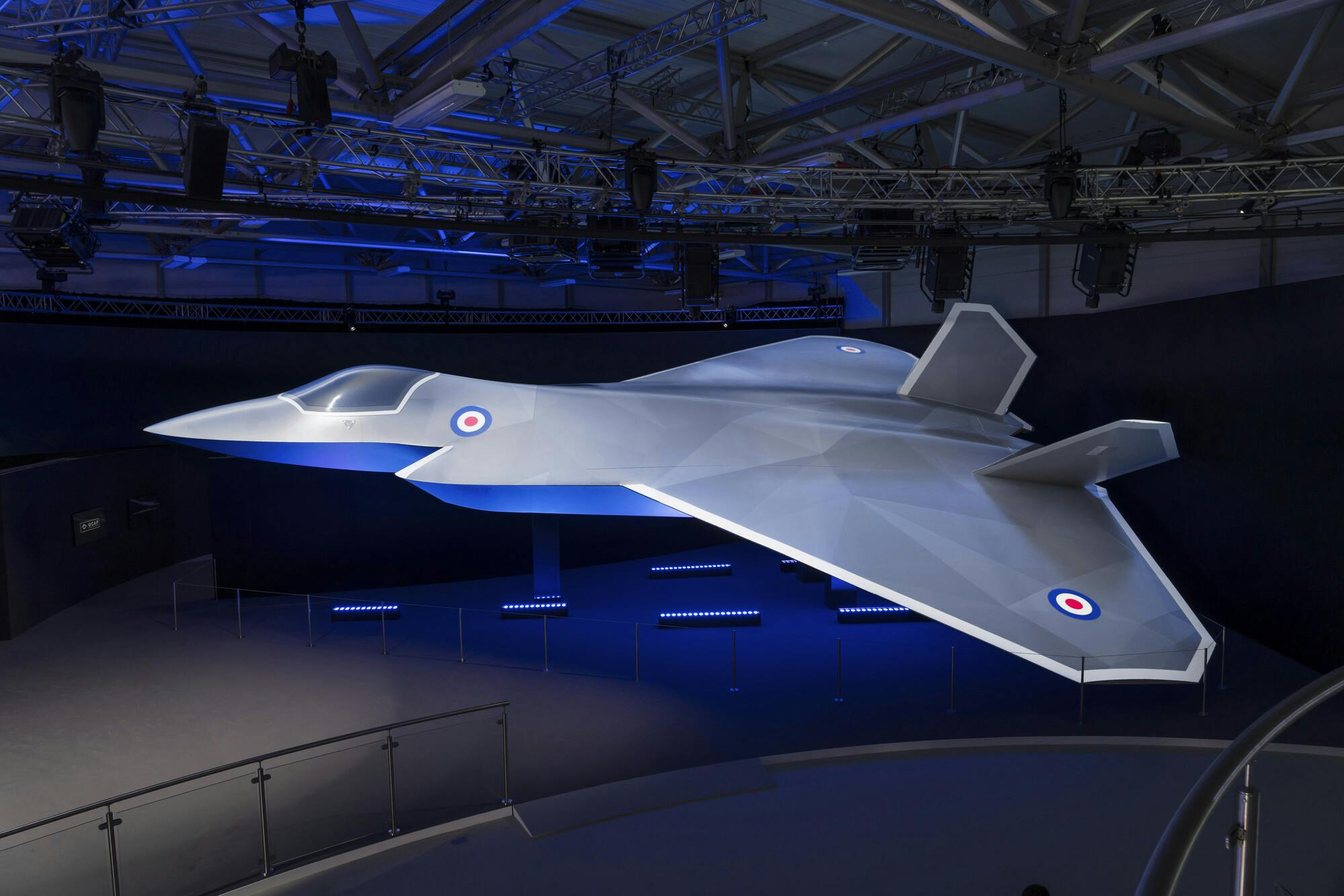

Earlier this month, the three nations of the Global Combat Air Programme unveiled a new concept model of their next-generation fighter aircraft at the Farnborough International Airshow 2024.

The new concept model displayed in Hall 5 features an evolved design with a larger wingspan to enhance the aircraft’s aerodynamics.

Herman Claesen, Managing Director of Future Combat Air Systems at BAE Systems, highlighted the progress made since the programme’s launch:

“In the 18 months since the launch of the Global Combat Air Programme, we’ve been working closely with our industrial partners in Italy and Japan under the collaboration agreement, and also with the three governments, to understand and align requirements for a next-generation combat aircraft. The new model, unveiled at Farnborough International Airshow, shows notable progress in the design and concepting of this future fighter jet. We’ll continue to test and evolve the design as we move closer towards the next phase of the programme.”

Guglielmo Maviglia, Chief Global Combat Air Programme Officer at Leonardo, emphasised the programme’s rapid pace and strong commitment:

“The pace of the programme is extraordinary, building on a solid foundation and industrial legacy in each country and government-led partnership. Since the treaty was signed in December 2023, the programme has seen strong commitment from each partner. Each brings different, but complementary, qualities and requirements. We are now working closely together to exchange knowledge, address common challenges, and achieve common goals.”

Hitoshi Shiraishi, Senior Fellow at Mitsubishi Heavy Industries, expressed the collaborative benefits:

“MHI considers any project to be a valuable opportunity to deepen our knowledge. In particular, since GCAP is a three-country joint development programme between Japan, the UK, and Italy, we expect to obtain better results and deeper knowledge than ever before by combining the different cultures, experiences, and knowledge of the three industries involved.”